Two leading edge industrial companies from Wollongong say it’s a significant achievement for their association to make the shortlist of finalist’s at the 2014 Endeavour Awards night.

Both Leussink Engineering and SOTO Consulting Engineers knew when they designed and built the SWIFTA it would be noticed, largely because no solution of its type truly existed anywhere in the world.

Leussink director Mr Jason Leussink says the close proximity of the two companies has helped forge the synergistic relationship.

“Being only a few blocks away from each other is very useful, but the big advantage is that we are on the same page when it comes to working out the most efficient solutions to a project or, as was the case with SWIFTA, answering a strong market need,” said Mr Leussink.

“With Soto’s strong presence as a consulting engineering firm in the Australian resource and manufacturing sectors, they are very capable in designing all types of solutions and prototypes and with our plant just around the corner we dovetail nicely operating as the production side of the equation.”

To Soto Consulting Managing Director Mr Frank Soto, the recognition of SWIFTA – an all Australian designed and manufactured technology – by the strong Endeavour Awards judging panel in some way helps to quell the myth that Australia doesn’t make unique products anymore.

“I am sure most people would like to see Australia manufacturing more products as we did in the boom post war decades, but we can still design and manufacture first class products for the world market just as the SOTO-Leussink association proves,” said Mr Soto.

“So it is a proud achievement by both Leussink and SOTO to be recognised through these national awards and proof that engineering innovation for global application is a potentially fertile ground for capable Australian engineering companies.”

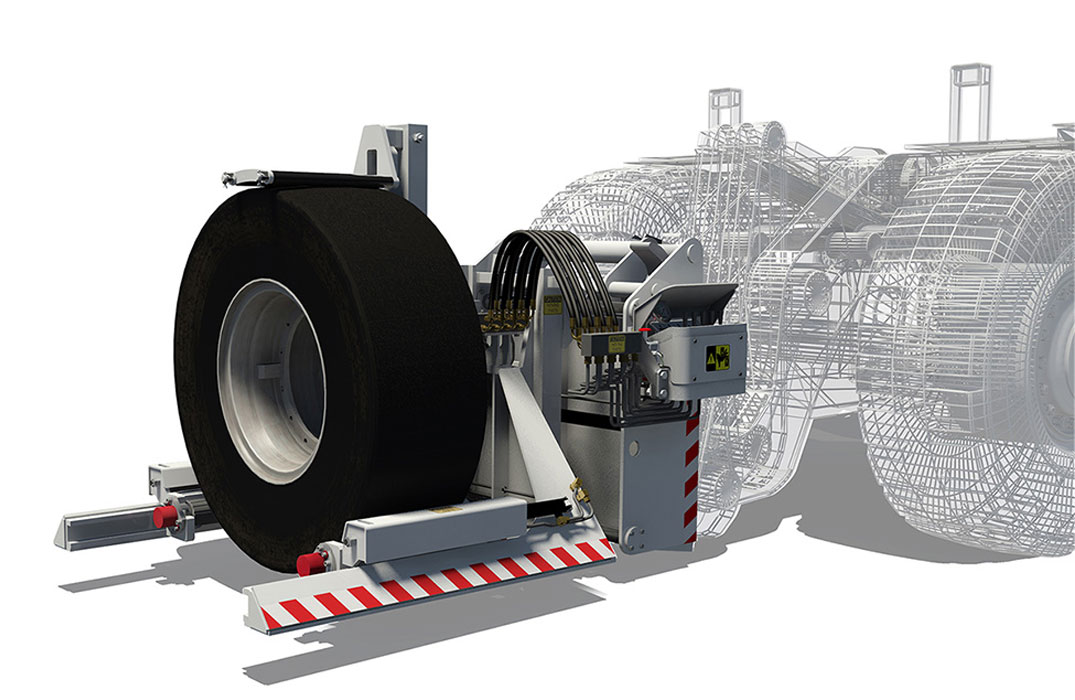

SWIFTA (Safe Wheel Installation Fitting Transportation Apparatus) is a patented development for safe wheel changing with LHDs (Load Haul Dumpers) within the underground mining environment.

The initial design, specifically for wheel sizes with dimensions ranging from 1200mm to 1435mm, exemplifies the high level of safety to which the design process has focused.

This unit eliminates much of the danger from the process because the operator is in control at all times.

The driver moves out of the LHD vehicle and come to operate the separate hydraulics panel on the SWIFTA; therefore everyone associated with the wheel change can see the wheel perfectly without obstructions while being safely removed from the potential crush zones, – which to date has been an industry risk because control has traditionally been done from the LHD.

But as soon as an operator begins to move from the LHD, the LHD is disengaged and “locked down” by an automatic safety device and the SWIFTA becomes the sole control point for the tyre change procedure.

Refer to this page to find out more about the SWIFTA.